Carbon dioxide capture

Due to the combustion of fossil fuels, power plants and industrial processes generate exhaust gases that contain high levels of carbon dioxide. Different procedures can be applied to reduce carbon dioxide emissions:

- Pre-combustion capture: carbon dioxide is removed from synthesis gases before combustion

- Post-combustion capture: carbon dioxide is removed from flue gases after combustion with air

- Oxyfuel capture: carbon dioxide is removed from flue gases after combustion with oxygen

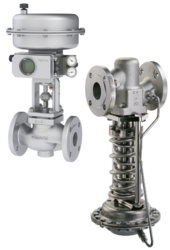

Globe and rotary valves by SAMSON are already being used in these procedures around the globe. SAMSON supplies special valves for the oxyfuel capture process.

Carbon dioxide transport

The removed carbon dioxide must be cleaned before being transported. By removing water from the gas mixture, corrosion during transport can be prevented. For the actual transport, the CO2-enriched gas is compressed or cooled down until it becomes liquid or reaches its supercritical phase. During transport, the pressure and temperature must be controlled accurately to prevent a phase transition and to stop the carbon dioxide from reaching its triple point (when there is a phase equilibrium between gaseous, liquid and solid phase).

SAMSON‘s product range includes different proven-in-use, corrosion-resistant valves to handle the pretreatment of the carbon dioxide and the actual carbon dioxide transport. Anti-surge valves, cryogenic valves, special HIPPS shut-off valves and ESD valves are reliable solutions for these applications.

Carbon dioxide storage

In CCS processes, the removed carbon dioxide is fed into the wellhead and permanently stored in layers of rock deep beneath the ground. To properly function in the environment of the injection point, the valves in such applications must be rugged to withstand the most challenging conditions and come with field capabilities.

SAMSON valves fitted with valve trims optimized for the process conditions fulfil these requirements.

Carbon dioxide utilization

In CCU processes, the captured carbon dioxide is put to further use. For example, it is utilized as a raw material in the chemical and petrochemical industries to produce polymers, building material and synthetic fuels. After it has been purified adequately, carbon dioxide can also be used in the production of foodstuffs and beverages.

The chemical industry and the food industry figure among SAMSON‘s key markets. As a one-stop shop, SAMSON provides light- and heavy-duty valves for chemical processes to meet all requirements. The same applies for special tasks, such as hygienic or sterile processes.

Innovative valve accessories, such as positioners and solenoid valves, round off SAMSON‘s product range. Smart instruments including our communication-enabled positioners allow for efficient asset management and predictive maintenance.

In the process industry, carbon dioxide may exist as dry ice, a gas, a liquid or a supercritical fluid depending on the pressure and temperature. Its state of aggregation and changes of phase play an important role in engineering carbon dioxide applications because of the different properties the substance possesses at varying phases.

SAMSON has comprehensive experience in sizing valves for carbon dioxide service at its liquid, gas and supercritical phase.

Our specialists will gladly assist you.

Carbon dioxide is generated when fuels (such as coal, crude oil, natural gas, biogas, wood) are burnt. This means that private households, traffic and industry contribute to the growing share of carbon dioxide in the atmosphere. Carbon dioxide reduction can only be achieved if industrial processes are changed and made more sustainable. After all, industry is one of the largest producers of carbon dioxide emissions.

Strategies to improve climate protection include the use of CCU and CCS technologies where carbon dioxide is captured, transported and stored or utilized as a raw material.

Apart from industry, traffic contributes considerably to the greenhouse effect by the combustion of fossil fuels. To change this, power-to-x technologies focus on generating synthetic fuels, such as kerosene, benzene and diesel no longer from fossil sources only. For this purpose, green electricity is used to split carbon dioxide and water into carbon monoxide and hydrogen to produce a raw material for fuels.